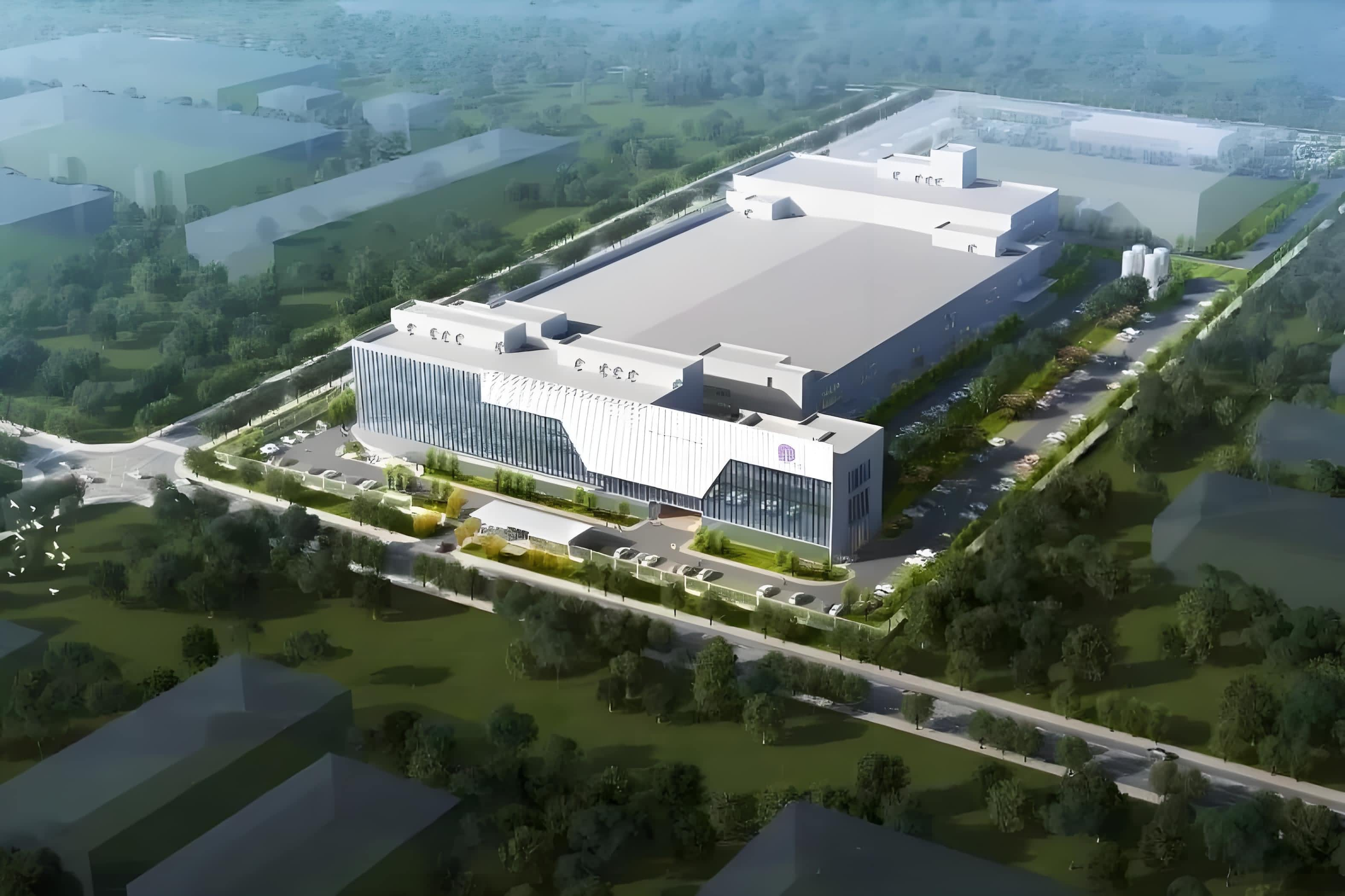

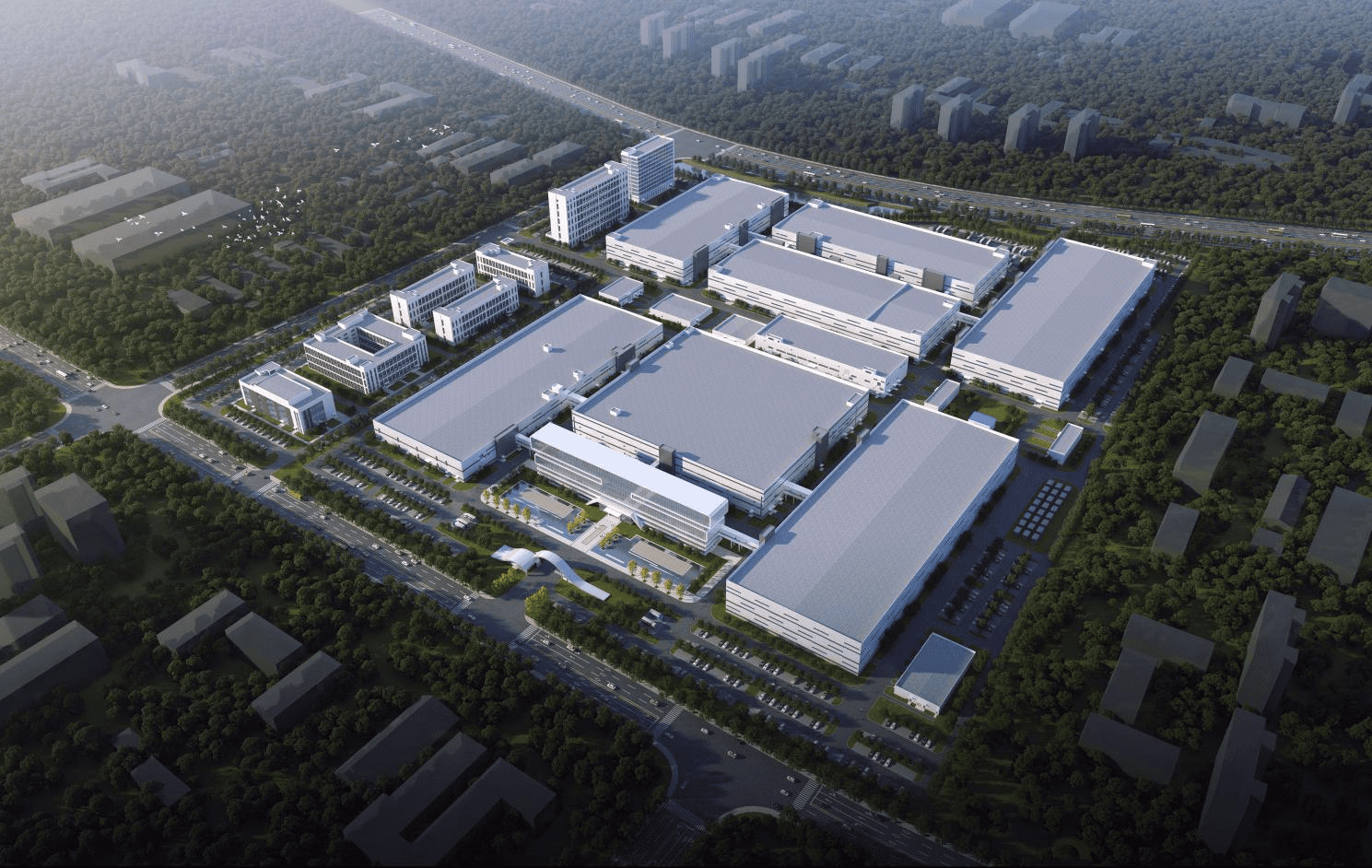

Headquartered in Singapore, UTAC is an industry-leading independent supplier of assembly and testing services for semiconductor chips. United Test Upowertek (Dongguan) Co., Ltd. is a company controlled by UTAC. On its chip packaging and testing production line, the high-definition image of the chip is taken by the industrial camera for intelligent quality inspection, and the data increment is large, but some pictures only need high-definition format for the first seven days to facilitate manual review, and only archive and retrieve after seven days, or delete directly. Shanyan intelligent data processing platform is used to convert BMP images into JPG images, and realize automatic lifecycle management based on image tags (such as automatic deletion of images when they expire, and archiving them to cold pools after transcoding). SandStone helps users save 90% of storage space, and the data processing efficiency is improved by 50% compared with traditional solutions, and the overall cost is reduced by more than 90%.

From 'Manufacturing' to 'Intelligent Manufacturing'

SandStone: Why does Liance Youte Semiconductor adopt distributed storage as the cornerstone of its IT infrastructure in the process of digital transformation?

UTAC Wang Zhilin: Liance Youte Semiconductor (Dongguan) Co., Ltd. is a company under UTAC Holdings. UTAC Holdings Limited is an independent supplier leading the industry in providing assembly and testing services for various semiconductor chips. We provide a full range of semiconductor assembly and testing services in these major product categories: analog devices, mixed signal and logic devices, and memory. Headquartered in Singapore, with production bases in Singapore, Thailand, China, Indonesia, and Malaysia.

As a company specializing in semiconductor chip packaging and testing, its manufacturing process has high requirements for the automation and intelligence of production equipment. With the continuous development of intelligent manufacturing, Liance Youte Semiconductor is also constantly promoting digital transformation and the application of AI technology. In this process, a large amount of data will be generated, mainly unstructured data. Considering the performance characteristics of distributed storage in processing unstructured data, we have decided to adopt a distributed storage solution.

New storage supports intelligent manufacturing

SandStone:What are UTAC's plans for utilizing distributed storage for enterprise production and manufacturing?

UTAC Wang Zhilin: In the process of selecting products and solutions, Liance Youte Semiconductor combined the characteristics of the data generated by the enterprise itself, examined different suppliers and solutions, and ultimately recognized SandStone's technological advantages in distributed storage. Our cooperation with SandStone mainly focuses on three aspects: firstly, achieving seamless connection between production equipment and storage equipment. We need to ensure that production data is stored on the storage without affecting the performance of production equipment. Secondly, it is necessary to achieve full lifecycle management of data in this process, by monitoring, organizing, and analyzing data during product usage to enhance the added value of enterprise services. Thirdly, we need to establish a fast query function based on massive data.

Liance Youte Semiconductor adopts SandStone MOS massive object storage, providing cross machine room unified storage for unstructured data to meet the storage needs of production workshops for data. Production storage consists of 8 nodes, divided into hot pool and cold pool. The hot pool is directly connected to the application program of the production machine, and the application program directly writes files to the hot pool. The hot pool data is managed through lifecycle management and regularly formatted by SandStone's intelligent processing framework. The processed images will be transferred to the cold pool for storage. In addition, disaster recovery storage deployment has been implemented in the data center, where all data from the hot and cold pools are asynchronously replicated to the disaster recovery storage through policy settings. Prevent data loss caused by logical failures such as misoperation or physical failures such as a disaster in the entire data center.

As of now, our data has been formatted using the SandStone Intelligent Processing Framework, and the processed data size is 20% of its original size. Currently, the available capacity of our storage cluster has reached the PB level, and we will also expand accordingly with the increase of production in the future.

SandStone: In your opinion, which aspects of Sugiyama impressed you during the collaboration between UTAC and Sugiyama?

UTAC Wang Zhilin: During the entire project delivery process, SandStone did a great job in several aspects: first, the integrity of the entire scheme design; Secondly, flexibility in technology implementation; Thirdly, the timeliness of product delivery. Because the data we generate is massive, if it is not processed in a timely manner, the continuity of the production line will be affected. After adopting SandStone's massive object storage product, the production line can operate continuously 24/7, which is crucial for improving production efficiency.

New storage centered around 'data'

SandStone: What are the expectations of Liance Youte Semiconductor for data storage in the future?

UTAC Wang Zhilin: Data is stored, managed, and ultimately mined for information and value. Therefore, in the era of massive data in the future, our focus is not limited to the timeliness of data storage, but more on data management and mining, to explore the potential value of data and promote the development of intelligent manufacturing.

Inspection data management

quality inspection image storage

semiconductor packaging and testing

Industry Solutions

Industry Solutions

General Solutions

General Solutions