The factory is neatly arranged with highly automated intelligent equipment and production lines, fully replacing traditional manual operation modes in automated production. Taking SMT line as an example, the automation level is as high as 95%, the automation rate is increased by 17%, and the production line personnel are reduced by 68%. This is Xiaomi, Honor OPPO、vivo、 The real scene of Longqi Technology Manufacturing Factory, a leader in the consumer electronics ODM (Original Design Manufacturer) industry and a major OEM manufacturer for mobile phone manufacturers such as Lenovo and Samsung.

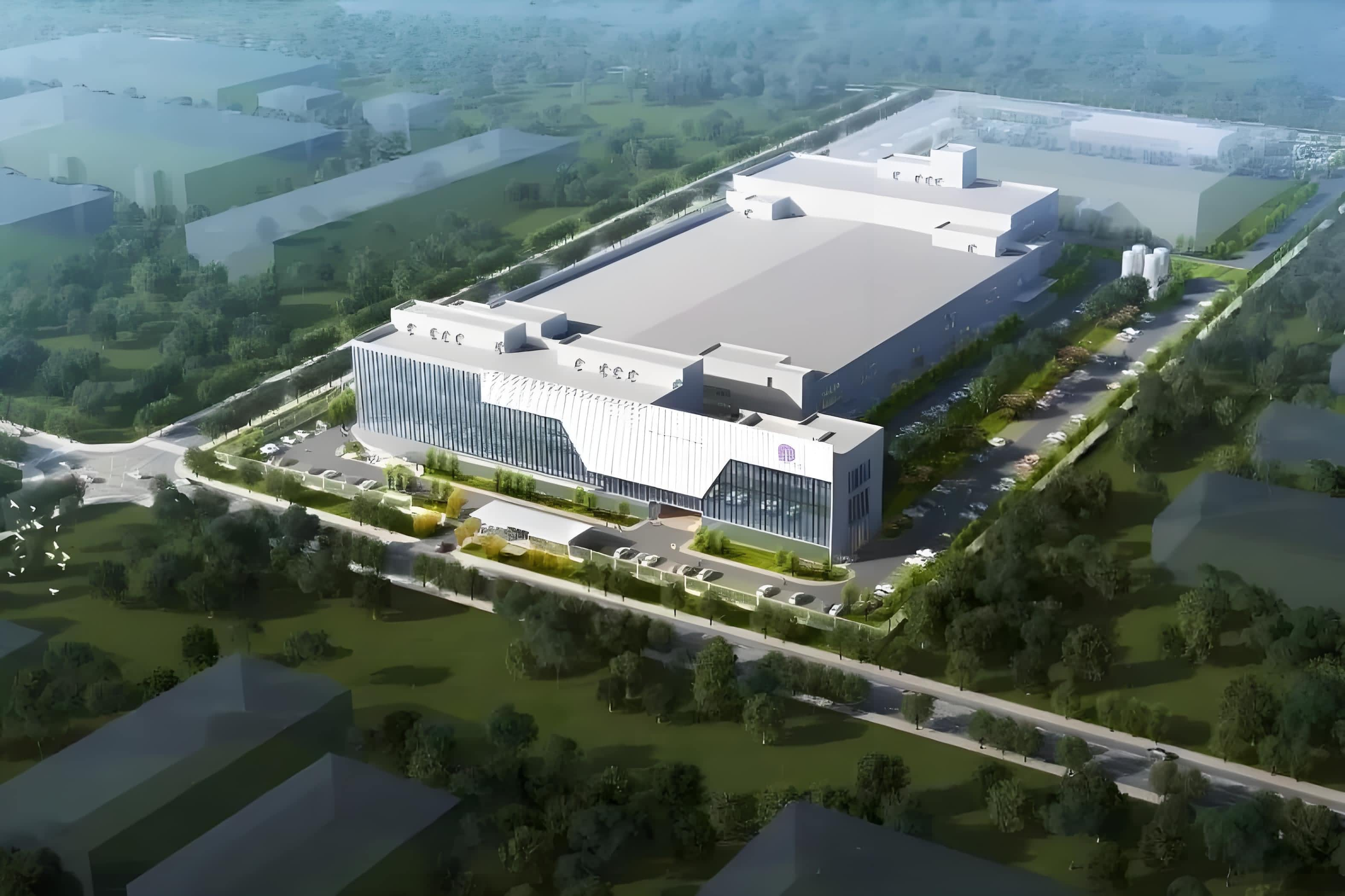

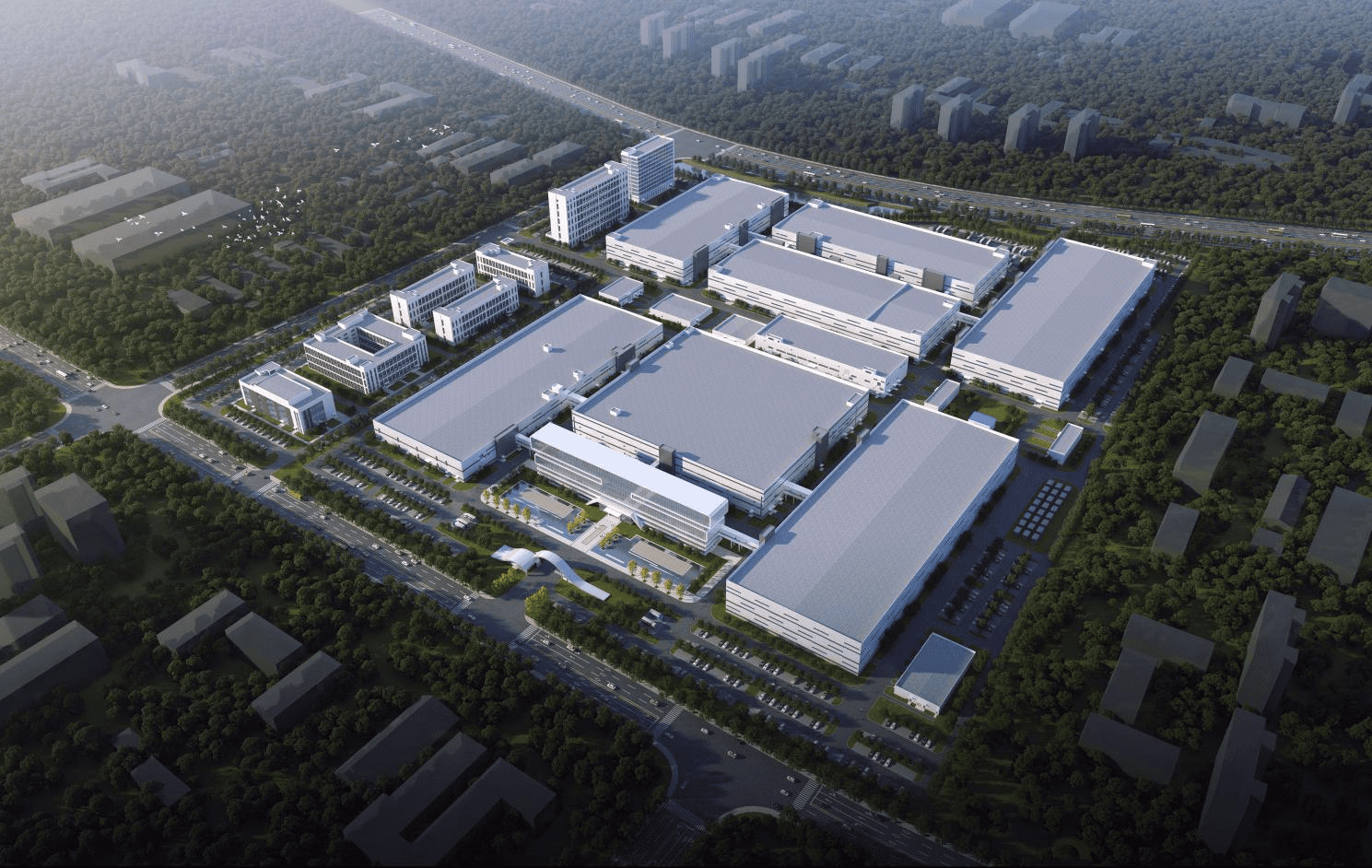

Longqi Technology Manufacturing Industry Base

In the past decade, the intelligent terminal industry represented by smartphones has flourished. As an important participant, Longqi Technology has been deeply involved in the ODM industry for over 20 years, focusing on the design, research and development, manufacturing, and service of terminal products such as smartphones, tablets, AI PCs, XR, AIoT products, and automotive electronics. Its business covers more than 100 countries and regions around the world, providing professional intelligent product solutions for top global customers.

Traditional architecture faces bottlenecks, highlighting the management challenges of nearly 2 billion production data storage

Longqi Technology's main customers include well-known consumer electronics brands in the industry such as Xiaomi, Samsung Electronics, Lenovo, Honor, OPPO, Vivo, etc. These customers highly value product quality and brand reputation, and have extremely high requirements for product quality and delivery capabilities from ODM manufacturers.

In order to meet the increasing demand for manufacturing process accuracy and complexity of products, and improve production efficiency, Longqi Technology has introduced a large number of intelligent equipment and production lines, and promoted digital management coverage. It has accelerated the deployment of the "Black Lamp Factory" plan, introduced various intelligent detection technologies in PCB board placement, PCB cleaning, solder paste printing, SMT, and whole machine bonding and packaging processes, and promoted the development of production, detection automation, and capacity flexibility, strictly controlling quality with a high standard production and operation system.

The operation of these intelligent production devices continuously generates a large amount of production logo logs, quality inspection images, and other data. In order to meet the quality traceability requirements of different downstream customers, Longqi Technology usually needs to archive production line data for more than 3 years, and some even for more than 10 years. With the rapid development of business, the total data volume of production lines in Longqi Nanchang and Huizhou manufacturing industrial bases has grown rapidly to nearly 2 billion, with a total capacity of several PB. Previously, Longqi Technology's various production lines used virtualization platforms and collected data locally through FTP virtual machines. With the rapid growth of data volume, there are various challenges in terms of data security, data management convenience, query convenience, capacity expansion, and planning

Low stability and single point of failure risk: Currently, several production lines are provided with data read and write services by multiple virtual machines, which poses a single point of failure risk at the architecture level. After a failure occurs, there is no HA high reliability mechanism, and any virtual machine server failure can cause business interruption and data loss. At the same time, existing platforms rely on the stability of virtualization platforms and are unable to timely detect hardware aging and replacement issues such as the expiration of hard disk service life, making it difficult to guarantee business stability.

Slow and inefficient data retrieval: The existing virtual machine storage service equipment management and data applications cannot provide visual operations. Nearly 2 billion test log logs and image files are distributed in different storage spaces. When quality backtracking, data retrieval needs to be manually queried among numerous historical virtual machines, which is time-consuming, laborious, and inefficient.

Difficulty in data management: Archived log files cannot be automatically cleared according to the quality control cycle requirements for quality traceability. Manually deleting files poses security risks such as misoperation and malicious data deletion.

Difficulty in storage space planning: The existing log storage space is about to be filled and data continues to grow. Test log file data cannot be compressed or archived, storage space cannot be reused, and expansion is cumbersome. It is expected that the demand for storage will continue to increase in the future as production line capacity increases, leading to difficulties in storage capacity planning.

Combining Shanyan data to solve the problem of data storage and management

For the above challenges, after rigorous technical testing and verification of numerous product solutions in the market in the early stage, Longqi Technology has found Shanyan Data, which deeply cultivates the intelligent manufacturing industry scene and provides massive data storage and management solutions, to easily solve the problems with a set of intelligent data storage and management solutions for production lines.

Data aggregation: In response to the problem of single point of failure in machine data writing, which can easily cause front-end industrial control computer business downtime, the new solution connects the front-end application system through FTP tools and Shanyan iDataFusion intelligent data fusion system, aggregates and verifies data in real time, achieves smooth migration of historical logo logs and quality inspection image data, and automatically aggregates data to a new storage pool to avoid business downtime caused by single point failure risks.

Data storage: In response to the difficulties of cumbersome expansion, difficult space planning, and inability to reuse storage space in traditional storage architectures, the new solution adopts a universal rack mounted server and deploys the Shanyan MOS massive object storage system. It adopts a fully distributed architecture, with unified capacity management and on-demand distribution. In the later stage, it can be flexibly expanded as needed, and the capacity and performance increase linearly with the increase of storage nodes, which can meet the storage capacity requirements under rapid data growth; After enabling the compression function, cold data compression archiving is achieved, which increases space utilization by 566% and significantly reduces storage costs.

Data retrieval and management: Addressing the challenges of time-consuming and labor-intensive manual operations for raw data retrieval, as well as the inability to centralize, unify, and quickly retrieve data. The new solution uses the Shanyan Intelligent Data Management System (Shanyan iDataExplorer) to label the data files generated by various devices based on parsing information, automatically generating multi-dimensional label information such as machine name, date, process, positive and negative extreme values, while retaining the original query dimensions such as SN and barcode. During quality traceability, specific files can be quickly queried based on the labels. In terms of data management, by configuring lifecycle management strategies and automatically deleting files that no longer need to be saved according to quality control requirements, business efficiency is greatly improved.

Data security guarantee: The host redundancy adopts a distributed architecture (multi node), and the data redundancy adopts more efficient protection mechanisms such as erasure codes and replicas. It comes with multiple versions of files, CDP and other technologies to achieve real-time backup protection of data, without the need for dedicated backup networks and backup software. By implementing graphical interface operations, automated and strategic operation and maintenance management, such as system automation installation and deployment, automated configuration, online upgrades, software and hardware system automatic monitoring and alarm push, management and operation and maintenance are simpler and more efficient.

Customer benefits: greatly improved production line data management, data retrieval in seconds, and overall cost reduction of 60%

Through close cooperation with Shanyan Data, Longqi Technology has built a stable, reliable, unified management, open and compatible one-stop production line data storage base, which provides solid support for high-quality operation of production line automation and intelligence, supports the achievement of business objectives, and has achieved the following benefits:

100% compliant storage of production line data to avoid disputes and fines caused by data loss. The data from tens of thousands of testing machines and terminals on all production lines are automatically aggregated and centrally managed. Through a distributed architecture, capacity can be expanded as needed, data can be safely and reliably stored, and business operations are not interrupted. Compared with the original single machine deployment mode, it avoids production line downtime caused by downtime. Any hardware such as node or disk failures are imperceptible to front-end business, data is not lost, and the cost of purchasing backup software is saved (about 300000 yuan/year).

The query efficiency of quality traceability files has been improved to seconds. Centralized retrieval of data from multiple production lines, using hash algorithms and custom tag retrieval technology to quickly search for specified files under nearly 2 billion data points. The file search time has been greatly increased from the hourly level to as fast as 1 second, greatly optimizing product quality traceability efficiency and helping Longqi Technology win more orders.

Improve the efficiency of operation and maintenance management. Abandoning the original solution of managing multiple FTP virtual machines, avoiding frequent virtual machine switching, achieving unified data storage and retrieval, and achieving horizontal expansion of storage cluster capacity and performance, with simple and easy to operate expansion; Unified monitoring of operational status and real-time alerts, visual interface management, greatly improving management efficiency.

Reduce TCO by 60%, significantly reducing storage construction costs and labor costs. The solution is based on a universal server to reduce storage hardware costs; By utilizing lossless data compression and meeting quality traceability requirements, the space utilization rate is increased by 566%, saving storage costs; Automatic deletion of expired data significantly improves business efficiency and reduces ineffective manpower investment by over 90%.

Facing the future, leading manufacturing companies focus on the hidden value of data

Currently, the manufacturing industry is accelerating the pace of intelligent manufacturing. Major manufacturing companies are competing to innovate production models such as smart devices, smart production lines, smart workshops, and smart factories, which will generate massive amounts of production logs, quality inspection images, equipment operating parameters, and other data. As the foundation for enterprises to achieve digitalization, informatization, and intelligent management, production line data will play an important role in value. How to scientifically and reasonably collect, transmit, store, manage, analyze, and apply data, and explore the value behind the "gold mine" of data, is a topic that leading manufacturing enterprises like Longqi Technology are exploring and practicing.

In the tide of intelligence, the transformation of traditional manufacturing to intelligent manufacturing requires the help of external power and resources. Shanyan Data has always adhered to the concept of "customer-centric, focusing on industry scenarios" in the field of intelligent manufacturing. By providing intelligent data storage and management solutions for production lines, we aim to achieve zero loss of production line data, zero business interruption, cost reduction and efficiency improvement for our customers, and continuously create value for them. This is also the basis for leading companies in various manufacturing sub sectors such as BYD, BOE, Shenzhen Technology, Jabil Electronics, Weixin Electronics, Crystal Optoelectronics, Honeycomb Energy, Yisiwei, and UTAC to choose to cooperate with Shanyan Data for win-win results.

Currently, China is moving towards the goal of becoming a "manufacturing powerhouse". High end manufacturing industries such as new energy power batteries, semiconductors, panels, and consumer electronics are racing to break free from constraints, explore the hidden value of data, achieve information integration between IT and automation systems, improve the efficiency of intelligent manufacturing, and promote the implementation of the concept of smart factories.

Testing data management

quality inspection image storage

electronic manufacturing

Industry Solutions

Industry Solutions

General Solutions

General Solutions