Customer Introduction

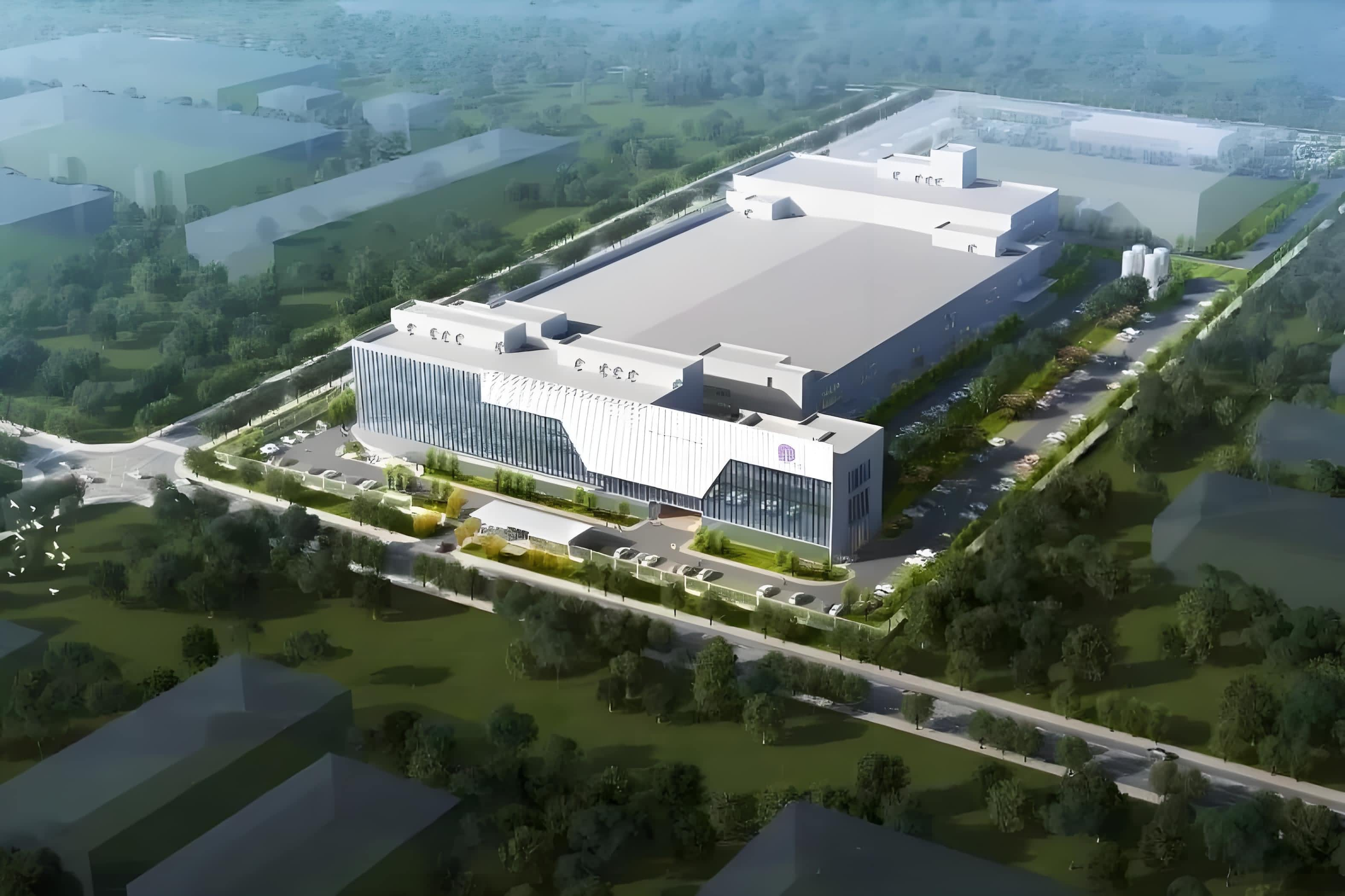

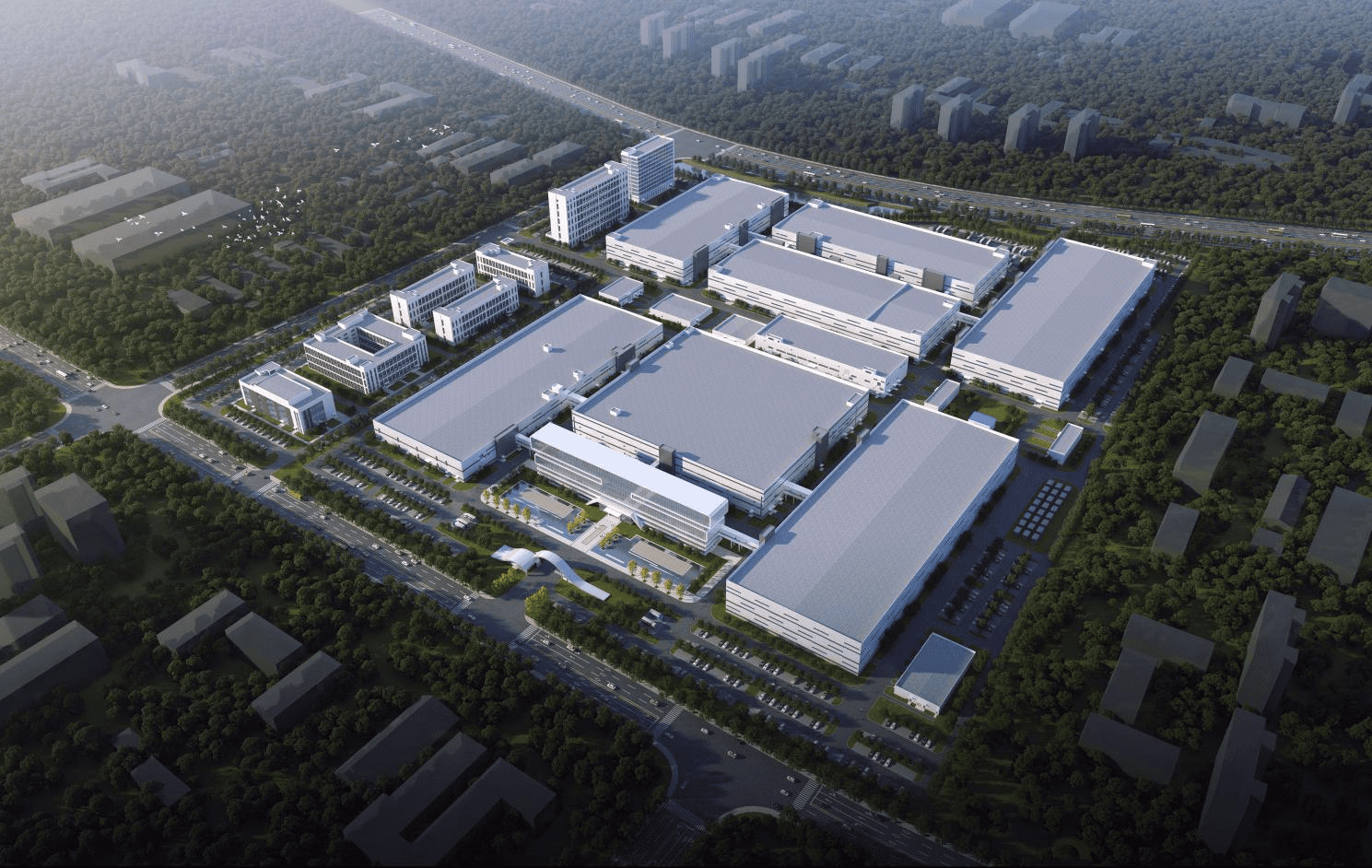

Sunway Communication (Jiangsu) Co., Ltd. (hereinafter referred to as Jiangsu Sunway) is a wholly-owned subsidiary of Shenzhen Sunway Communication Co., Ltd. Its parent company, Sunway Communication, is a globally leading one-stop pan RF solution provider. The company's main products include antennas, wireless charging modules and magnetic materials, RF front-end devices, EMC/EMI RF isolation devices, cables and connectors, and R&D, manufacturing, and sales of audio/RF modules. Its customers are mainly world-class consumer electronics companies such as Apple and Huawei.

Due to the fact that the customers served by Jiangsu Sunway are all leading enterprises in the consumer electronics industry, these leading enterprises have extremely high requirements for the full process traceability and control of supplier product quality, requiring manufacturers to have high levels of automation, intelligence, and digitization. To this end, Jiangsu Sunway's digital transformation continues to deepen. In addition to manual visual quality inspection, a large number of automated inspection equipment, such as LCR, AOI, AI visual inspection equipment, etc., have been invested to firmly grasp the key links of product quality control in production processes and techniques.

Machine vision is both an opportunity and a challenge

The introduction of automated inspection equipment such as machine vision has improved product quality and production efficiency of intelligent manufacturing, but with it, the number and precision of product inspection images that need to be taken have also skyrocketed; At the same time, with the needs of customers and their own business management, various structured and unstructured data such as equipment process configuration parameter files, video files, database files, etc. need to be stored and accessed quickly, and traditional storage architectures are inadequate. The main challenges are:

The massive quality inspection image data generated during the production process is scattered and stored in quality inspection equipment on different production lines, resulting in long retrieval time for application systems and inconvenience in data management and retrieval.

To meet the traceability requirements of product quality, quality inspection pictures often need to be kept for more than 2 years. Traditional NAS storage has high investment costs when facing large capacity data backup. Moreover, due to the lack of data protection measures, once individual hard drives are damaged, data cannot be recovered, posing a security risk.

The storage system cannot be connected to business systems such as MES, and the subsequent processes cannot be quickly retrieved and called for quality analysis and operational analysis, which restricts the overall production level of the production line.

Joining hands with Shanyan Data to create an intelligent storage platform

Faced with the growing demand for storage of quality inspection images on production lines, Jiangsu Sunway hopes to build an efficient, safe, reliable, and user-friendly storage architecture to achieve the automation and intelligence of production lines. Distributed storage has become the preferred choice for upgrading intelligent manufacturing storage architecture due to its high performance, elastic scalability, and secure and reliable advantages.

The timeliness, security, and ease of use of data storage are our company's main demands for distributed object storage, especially for the convenience of data usage. Whether files stored in a distributed manner can be quickly retrieved, whether they can be smoothly connected to MES systems and other information systems, and whether they can provide various adapted interfaces for other systems to access quickly are of utmost importance, "said Yang Le, Manager of Jiangsu Sunway Information Technology Department.

After comprehensive comparison, Jiangsu Sunway chose to cooperate with SandStone Data and adopt SandStone MOS massive object storage to meet the storage and management needs of production line quality inspection data.

1. AVI and FLT re evaluation machines use the ES retrieval interface provided by SandStone Data to quickly extract files, and integrate with MES systems and other information systems to facilitate product quality analysis in subsequent processes. At the same time, data files and system operation monitoring can be viewed as needed.

2. Jiangsu Sunway uses the SandStone MOS intelligent data processing engine, combined with a file name parsing plugin, to label images generated by LCR, AOI, and AI visual devices based on parsing information, automatically generating labels such as timestamps, machine numbers, barcode serial numbers, etc. Quality inspectors and engineers can quickly retrieve specific image files based on the labels, improving retrieval efficiency and speed.

Intelligent storage adds the finishing touch to intelligent manufacturing machine vision

From installation and deployment to business launch, SandStone MOS's massive object storage has brought significant value to Jiangsu Sunway.

Safe and compliant, efficient access to massive quality inspection image data

With the expansion of the production line, the amount of data is showing a rapid growth trend. Jiangsu Sunway uses the production line of SandStone MOS, with a daily data storage capacity of hundreds of GB and a quantity of hundreds of thousands of sheets. SandStone MOS supports efficient access and future expansion of massive small files, automated data lifecycle management, and storage and management of data according to time and label policies, meeting the compliance requirements for long-term preservation of customer data. In the future, the NAS storage and file servers in the visual quality inspection equipment of various production lines can also be reused and managed, fully utilizing existing investments and meeting the needs of business scale growth.

Efficiency improvement, intelligent processing engine achieves millisecond level retrieval

Through the intelligent data processing engine of SandStone MOS, the data retrieval time of quality inspectors and engineers has been compressed from tens of seconds to milliseconds, providing effective technical support for business development.

System integration provides strong support for intelligent manufacturing

The AVI and FLT re evaluation machines quickly extract files through the ES retrieval interface provided by SandStone Data, and integrate with the MES system to provide strong support for subsequent product quality analysis and operational analysis.

The cooperation between SandStone Data and Jiangsu Sunway has equipped the application of big data intelligent storage in intelligent manufacturing with "sharp eyes and golden eyes". SandStone MOS not only solves pain points such as slow quality inspection data retrieval and difficult data sharing management for customers, but also proves the benefits of SandStone MOS intelligent data processing engine in data value utilization, which is a successful practice of traditional IT infrastructure evolving into a new distributed intelligent infrastructure.

Regarding this collaboration, Yang Le said, "From visual inspection with human eyes to upgrading production line automation and intelligence through LCR, AOI, and AI visual inspection technologies, the manufacturing industry has achieved rapid improvement in production efficiency. SandStone MOS's massive object storage can centrally manage structured and unstructured data, and provide intelligent data processing and service capabilities in combination with business needs, which is the most efficient way of data management

Testing data management

quality inspection image storage

electronic manufacturing

Industry Solutions

Industry Solutions

General Solutions

General Solutions