With the rapid development of electrification and intelligence in automobiles, the functional safety of components is increasingly valued by the automotive industry. As the core component of new energy vehicles, power batteries account for about 40% of the total vehicle cost, directly affecting the range and safety of the vehicle. For automobile manufacturers, once product quality defects are discovered after public sales, the cost of returns, claims, and damage to brand reputation will be incalculable. Therefore, ensuring the quality, safety, and reliability of power battery products, as well as the traceability of the entire production process, has become one of the important requirements put forward by automotive brands for supply chain enterprises. This means that enterprises that do not meet the relevant requirements will not be able to enter the supply system of downstream customers.

As a leading global manufacturer of soft pack power and energy storage batteries, Funeng Technology has won the favor of top global car companies by defeating several global first tier power battery companies with its ultra-high energy density and other technical indicators. And Funeng Technology is also constantly innovating in technology, using innovative production line data management methods to achieve full traceability of the production line process, meet the high quality requirements of more customers, and continue to maintain its technological leading advantage in the industry.

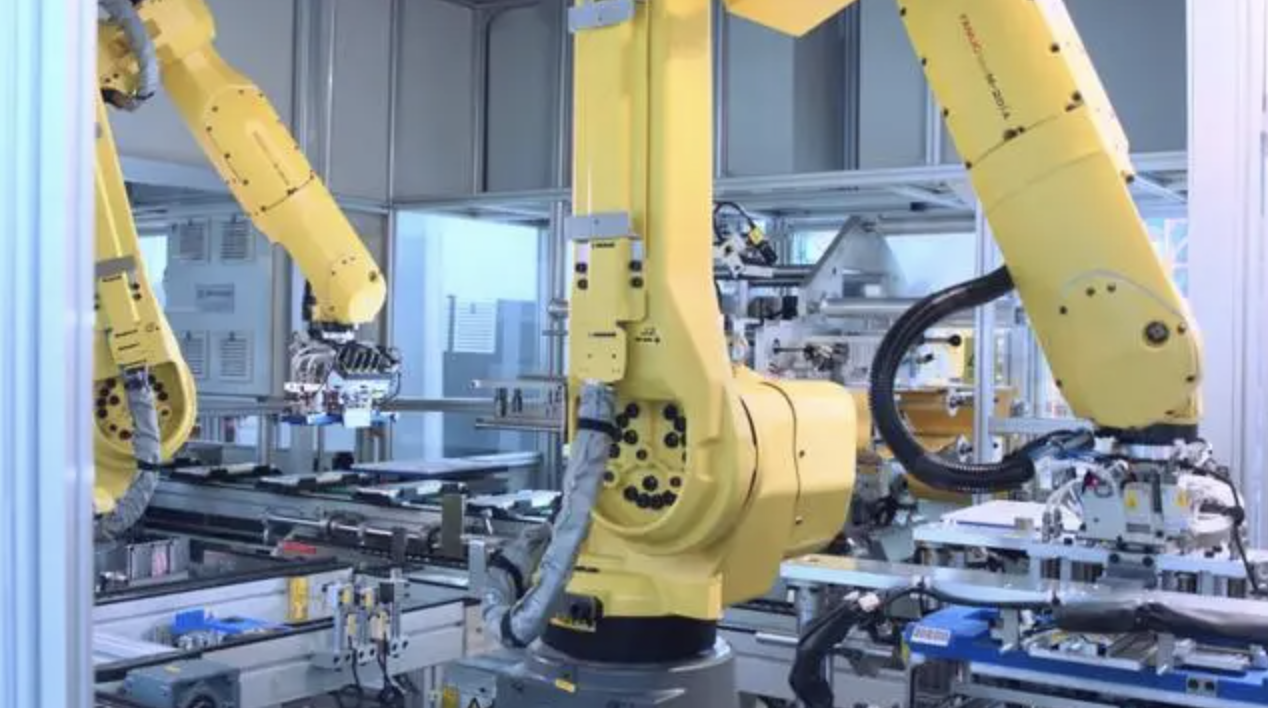

Comprehensively building high-end production capacity, Funeng Technology vigorously promotes intelligent manufacturing

Funeng Technology is a leader in new energy soft pack power batteries. In 2020, it was listed on the Science and Technology Innovation Board of the Shanghai Stock Exchange, becoming the "first stock of soft pack lithium-ion power batteries". Its core product, the ternary soft pack power battery, has excellent performance, including high energy density, good safety performance, long cycle life, fast charging speed, and strong temperature adaptability. With excellent battery performance, Funeng Technology has consistently ranked first in China's soft pack power battery shipments since 2017, and its customers cover many mainstream car companies worldwide.

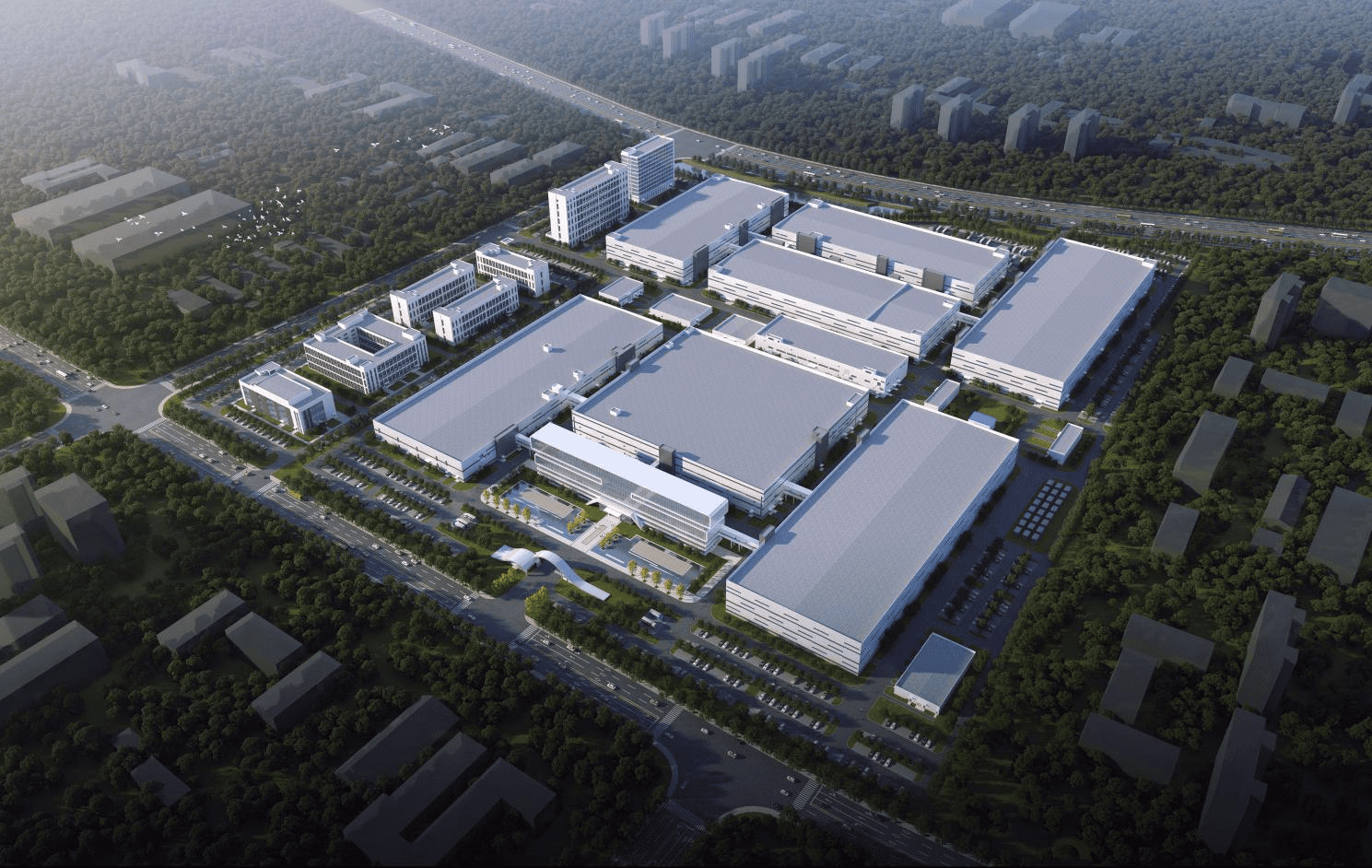

With the rapid development and growth of Funeng Technology's business, the factory has gradually expanded its production lines and capacity. Its intelligent manufacturing factory for power batteries has been designed with the goal of becoming an "Industry 4.0 intelligent production base" from the beginning, comprehensively creating high-end production capacity, and introducing the Internet of Things and big data into the intelligent manufacturing system to achieve intelligent detection, intelligent logistics, intelligent judgment, intelligent processing, intelligent storage, etc.

Customer Challenge: How to calmly deal with 20PB/year of production line testing data?

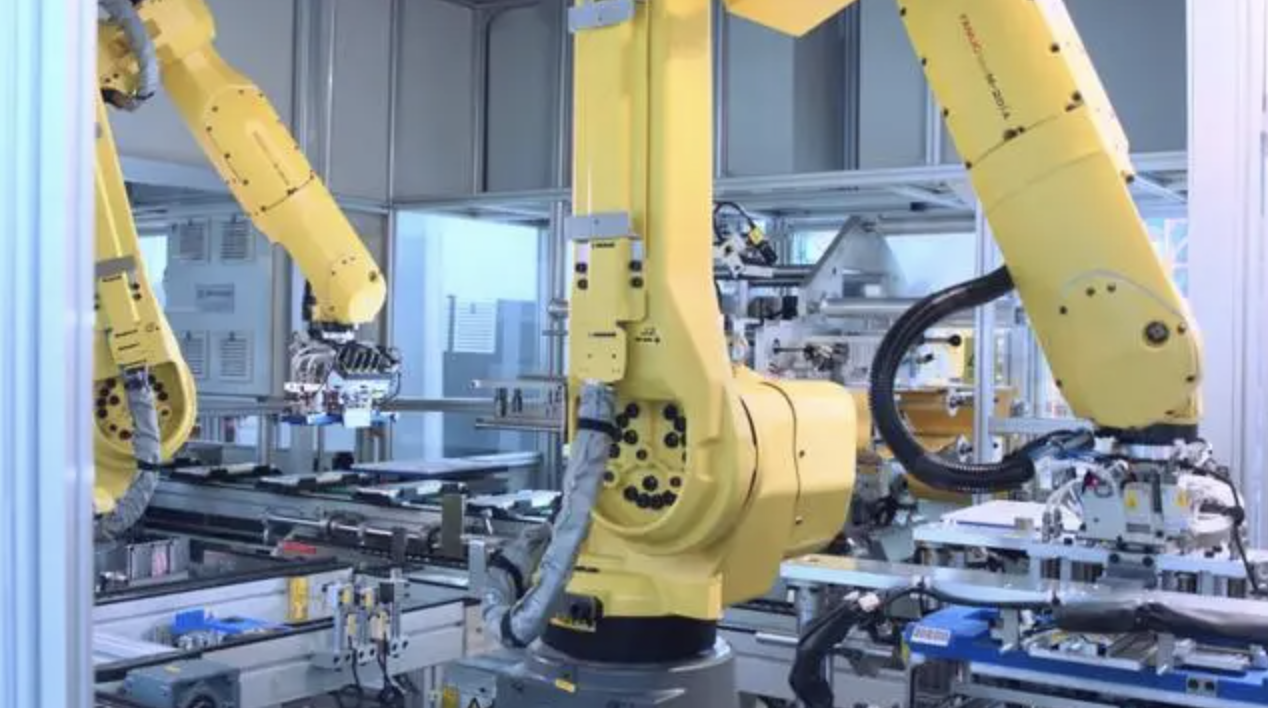

In the production process of the Funeng Technology factory, various intelligent detection equipment and systems operate continuously, and industrial cameras take photos to generate a large amount of defect detection image data.

Taking the Funeng Zhenjiang factory as an example, there are currently nearly a thousand CCD devices and dozens of battery cell sorting machines. These devices add nearly 100 TB of data every day. In response to the quality control requirements of downstream automotive manufacturers, according to different processes, the production quality inspection data of power batteries is required to be stored for as short as 1 year and as long as 15 years. The estimated total storage capacity requirement is 20PB/year.

Funeng Technology has previously adopted centralized NAS storage from multiple brands and used open source tools such as FTP for data aggregation and access. With the continuous growth of data volume, it faces various challenges such as insufficient storage capacity, cumbersome expansion, inconvenient data retrieval and calling, low storage reliability, and high construction costs

The amount of data is huge, but the storage space is insufficient

In response to downstream customer data retention requirements, all quality inspection data is required to be archived for 15 years, with an expected data volume of 20PB/year. However, the current data archiving is in traditional centralized NAS storage, with a capacity utilization of 80%. The expansion of the existing centralized NAS is limited due to its architecture characteristics, which cannot meet and adapt to the requirements of future storage performance and linear capacity expansion, and cannot store data for a long time. Therefore, it is necessary to plan and research new production line data storage solutions.

Low image retrieval efficiency during quality traceability

When conducting product quality traceability, due to the fact that data from different workshops are archived in storage of different brands, if it is necessary to search for corresponding batch defect image data, it can only be searched by file name or directory hierarchy in the corresponding storage space, which is inconvenient and inefficient to retrieve; Especially when accessing a large amount of quality inspection image data at once, limited by storage performance, retrieval time is long, and even folders cannot be opened, which affects the production progress and quality traceability efficiency of subsequent processes.

Large machine resource occupation and low storage reliability

Currently, all machine data is aggregated to NAS storage through open source tools, which consume a significant amount of machine resources, especially memory and hard drives. This has seriously affected the AI software re evaluation process of the machine itself and impacted business efficiency; In addition, the FTP protocol shares mounted data, and the reliability of access depends on the network. Once the network fails, it will affect production; The existing NAS has a single point of failure problem and lacks a highly reliable HA mechanism. In the event of equipment failure, there is even a risk of business interruption.

Massive data requires long-term archiving, resulting in high storage construction costs

According to the IT department of Funeng Technology, only more than half of the existing CCD devices are connected to storage devices for storing defect images. In the later planning of the storage system, all devices need to be connected and all quality inspection data needs to be saved for 15 years, requiring a large storage capacity space. However, high-end NAS is more expensive, low-end NAS has poor performance, difficult capacity space planning, and cannot automatically archive to low-cost media, resulting in high storage construction costs.

Customer Action: Join hands with Shanyan Data to solve the problem of production line detection data management

For the above challenges, Funeng Technology urgently needs to plan a new production line data storage and management solution to meet the problem of efficient data storage, management, and use. After comparing numerous product solutions in the market and conducting rigorous technical testing and verification, Funeng Technology has found Shanyan Data, which is deeply involved in the intelligent manufacturing industry and has rich practical experience in the power battery industry, to easily solve difficult problems with a set of production line quality inspection data management solutions.

Data aggregation:

Funeng Technology has replaced the original collection tool with the Shanyan Intelligent Data Fusion System (Shanyan iDataFusion), which allows for batch setting of machine collection task strategies, customization of upload time, frequency, file upload area, and format, and automatic full and continuous incremental uploading of data from various machines such as punching machines, laminating machines, welding machines, and gluing machines.

Set a bandwidth threshold upper limit during the upload process to minimize resource usage, and check the consistency of data on both ends. After the transmission is completed, delete the machine data to avoid the machine's hard disk space being full and improve the stability of business operation.

During the upload process, custom tag information such as machine, positive and negative extreme values, SN code, etc. will be added according to the strategy to provide support for quick retrieval of subsequent files.

Data storage:

The new solution adopts a distributed object storage architecture, with 5 nodes deployed in the early stage and a storage capacity of 3PB. Subsequently, based on demand, only additional servers or hard drives need to be added annually to achieve linear expansion of capacity and performance, which can meet the long-term storage requirements of massive data. Allocate storage space and performance according to the production capacity requirements of different processes, ensuring stable storage performance with a file volume of billions.

At the same time, the solution heterogeneously manages existing third-party NAS devices without the need for data migration, providing unified storage space to the outside world, fully utilizing old resources, and saving investment.

In terms of storage reliability, the storage system provides multiple data security mechanisms such as file multi version, directory level CDP, EC, and replica mechanisms to ensure data security and reliability.

Data management:

After saving the original inspection image data of Funeng Technology factory, it can be used for data analysis as soon as possible. After the analysis is completed, it can be converted/compressed through the Shanyan Intelligent Processing Platform (Shanyan iDataCook) to reduce storage space occupation. Combined with data lifecycle management, it can automatically delete expired data or automatically archive it to a cold storage pool.

Based on the needs of different departments such as IT, equipment, and quality, refine corresponding business permissions, such as creating different user groups and users for different factories, granting different permissions for data management, data retrieval, etc., and standardizing business processes.

Quick data retrieval:

By automatically parsing and tagging file names during the collection and upload process, Funeng Technology has achieved custom multi-dimensional retrieval of specified data based on machine numbers, production dates, product models, and other factors.

After retrieval, preview and annotate directly in the upper layer application, download and package in batches, greatly improving the efficiency of data search and processing for quality traceability.

Significant benefits: machine detection data management efficiency increased by a hundred times, TCO reduced by 60%

Through close cooperation with Shanyan Data, Funeng Technology has achieved efficient management of production line data, providing solid support for high-quality operation of production line automation and intelligence, and has achieved the following benefits:

Improve quality traceability efficiency by a hundredfold

During quality traceability, data classification management and processing are achieved based on multi-dimensional labels such as process, judgment results, module codes, and cell barcodes. The billions of data in all factory areas are retrieved uniformly, and the retrieval speed is increased from hourly level to as fast as 1 second.

Online preview and annotation eliminate the tedious process of downloading and processing one by one, greatly improving business processing efficiency.

Machine data management is more worry free

Abandoning the original open source tool data collection method, realizing continuous data upload, unified storage, capacity expansion on demand, and easy operation of expansion.

Multiple data security protection mechanisms, no need to worry about a single point of failure on the hard drive interrupting business.

Fine grained permission settings to avoid hidden risks such as data misoperation, greatly improving data security.

Unified monitoring of operational status and real-time alerts, visual interface management, reducing inefficient manpower input by 90%.

Storage costs significantly reduced, TCO reduced by 60%

Through automatic data compression, the image size is reduced by 80% while meeting accuracy requirements, significantly reducing costs.

Through lifecycle management strategies, overdue data can be automatically deleted or transferred to cold storage according to retention time requirements (such as 1 year), saving storage space and reducing storage procurement costs.

epilogue

Currently, the competition in the power battery market is becoming increasingly fierce. The use of innovative technologies to continuously improve product yield and production efficiency, and achieve cost reduction under production scale, has attracted more and more attention from enterprises. Against the backdrop of traceability throughout the production process becoming an important requirement for entering the supply chain system, Funeng Technology has achieved rapid aggregation, unified storage, convenient management, and quick retrieval and retrieval of production line quality inspection data through cooperation with Shanyan Data. This has comprehensively improved its quality management efficiency, reduced data storage costs, and laid a good foundation for continuously improving intelligent manufacturing and digitalization levels, and assisting in rapid business development.

Testing data management

quality inspection image storage

power battery

Industry Solutions

Industry Solutions

General Solutions

General Solutions